Showing 17–32 of 36 results

-

-

-

-

CNC lathe

TCK56Y-BMT40 CNC horizontal lathe is a brand-new product designed and produced based on our factory’s many years of experience in designing horizontal CNC lathes and in line with market and development needs. The main performance indicators of this product have reached the international advanced level, with ultra-high precision and stability, and a high-rigidity structure with large cutting volume feed, allowing customers to obtain high-efficiency, low-cost, and pure German machine tools.

This machine tool can process shaft and disc parts.In addition to the functions of CNC lathes, it can also complete plane milling, drilling, tapping, straight groove, spiral groove and gear milling, etc. It has composite functions such as turning, milling and boring, and can realize the processing concept of one-time clamping and full completion., and can process rotating parts efficiently, in large quantities, and with high precision. The rigidity of the spindle, bed, tailstock and other components is reasonably matched in the design, which greatly improves the rigidity of the whole machine and ensures the stability during heavy cutting. Therefore, the external circle precision of this machine tool can reach IT6~IT7 level. As a general-purpose machine tool, it is particularly suitable for the high-efficiency, large-scale, and high-precision processing of rotating parts in the locomotive, aerospace, military and other industries.

The machine tool adopts mechanical, electrical and hydraulic integrated structure, with a compact and reasonable overall layout, easy to repair and maintain, and has the characteristics of high efficiency, high precision and high rigidity. Key purchased parts are purchased through bidding, and products from well-known domestic and foreign manufacturers are selected to ensure the high reliability of the machine tool. The whole machine adopts a fully enclosed protection structure, and the appearance conforms to the principles of ergonomics, is pleasant and easy to operate.

-

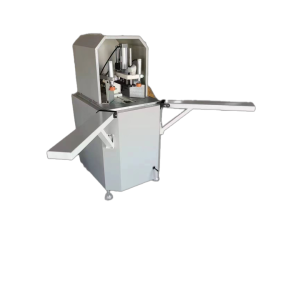

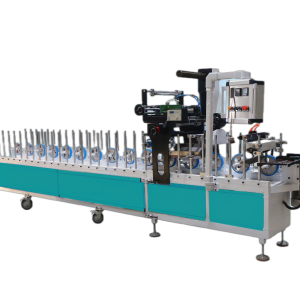

CNC milling machine

Aluminum profile CNC milling machine

【Equipment Features】

-Suitable for round hole, slot hole, keyhole and special-shaped hole of industrial aluminum

alloy profiles, doors and Windows, curtain wall combined gold profiles and aluminum profile

milling, chamfering, plane engraving and other processes of processing

-The main shaft adopts air-cooled motorized spindle to drive smoothly and effectively

improve the precision of the whole machine.

-All motion pairs adopt imported guide rails and sliding blocks. X axis adopts high-precision

helical gear and helical rack drive. Y axis and Z axis

Adopt high precision ball screw drive

-The working table can be turned 180 degrees, -90-0+90, and the profile can be processed

on three sides with one turn clip

The tool is equipped with automatic spray cooling device, which automatically cools during

milling and prolonging the service life of the tool

-Servo system, fast and accurate operation speed

-Simple operation, reliable performance, advanced technology, easy maintenance

-

-

-

-

-

-

-

-

-

-

milling cutter for cnc router & manual router

-

End Mills (Carbide or Tungsten)

For slotting, contouring, engraving, and general shaping. -

Spiral Bits (Upcut / Downcut / Compression)

Used for PVC and wood, ensures clean cuts without tearing. -

T-Slot Cutters / Dovetail Cutters

For frame joints and interlocking profiles. -

Aluminum Cutting Bits (Single Flute / Double Flute)

Designed for high-speed clean cutting of aluminum profiles.

-

-

End of content

End of content