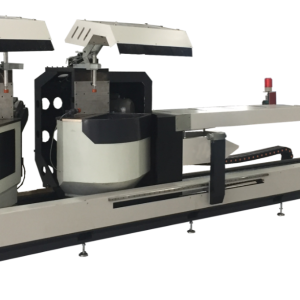

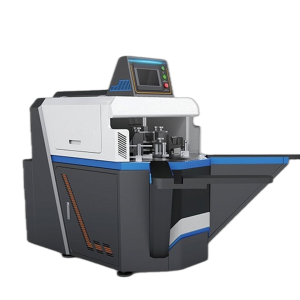

120 Corner Crimping Machine

120–Aluminium Profile Corner Crimping Machine

【Equipment Features】

The machine is one of the essential equipments for making of aluminum door & window. It is mainly used

for 90 joint extrusion and connection. Place an comer connector into the cavity between the two profiles

before corner combining. The hydraulic driving punching head make the profile keep its new form

permanently. This kind of joints of two profiles has much higher strength, higher efficiency and precision than any other means of corner connection